Knowledge

Classification of Steel Structures

Classification of Steel Structures

Classification Methods and Details of Steel

Structures

Steel structures can be categorized from multiple dimensions, primarily based on their purpose, structural form, connection methods, and fabrication techniques. Below is a detailed classification:

1. By Primary Use and Application Field

This is the most common classification method, directly related to the function of the structure.

1.Industrial Steel Structures

•Characteristics: Typically feature large spans and heavy load-bearing capacity (e.g., cranes, equipment), emphasizing practicality and economy.

•Typical Structures:

•Heavy industrial plants: Metallurgical, shipbuilding, and power generation plants equipped with heavy-duty cranes (e.g., >100 tons).

•Light industrial plants: Electronics, textile, and food processing factories, often using portal frame structures.

•Warehouses and logistics centers: Large spaces with high clearance, commonly used for storage and sorting.

2.Commercial and Public Building Steel Structures

•Characteristics: Focus on architectural aesthetics, spatial experience, and natural lighting. Structural forms are often more complex and innovative.

•Typical Structures:

•High-rise and super high-rise buildings: Office towers, hotels, apartments. Often use steel frame-bracing systems or steel frame-concrete core tube hybrid systems.

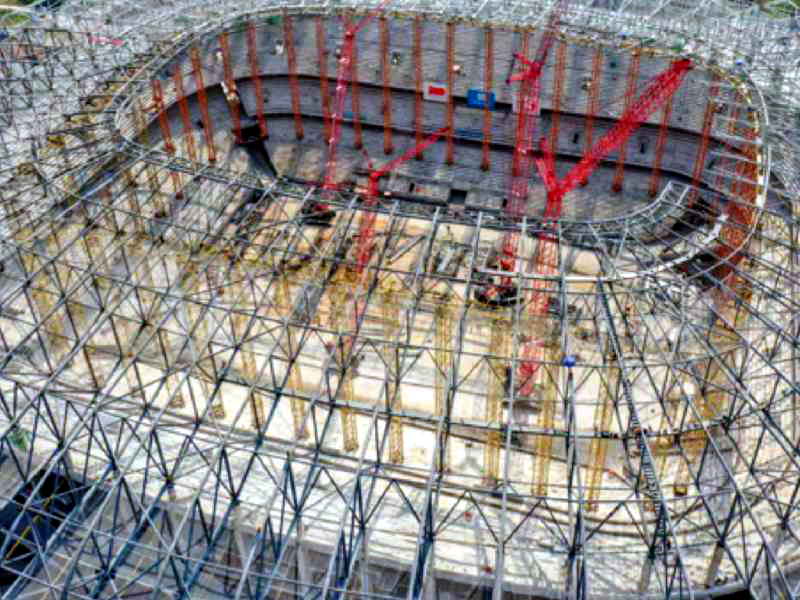

•Long-span spatial structures: Stadiums, theaters, airport terminals, exhibition centers. Commonly employ space trusses, latticed shells, tubular trusses, beam-string structures, cable-membrane structures, etc.

•Commercial complexes: Shopping malls, large supermarkets.

3.Bridge Steel Structures

•Characteristics: Subject to dynamic loads (vehicles, wind), requiring extremely high fatigue resistance and durability.

•Typical Structures:

•Plate girder bridges

•Box girder bridges

•Truss bridges

•Arch bridges (e.g., concrete-filled steel tubular arch bridges)

•Bridge towers and stiffening girders for suspension bridges and cable-stayed bridges.

4.Tower and Mast Steel Structures

•Characteristics: Tall structures primarily resisting wind loads, requiring high stiffness and stability.

•Typical Structures:

•Transmission towers

•Communication towers (e.g., microwave towers, broadcast towers)

•Wind turbine towers

•Towers and furnace structures in petrochemical facilities

5.Offshore Platform Steel Structures

•Characteristics: Operate in extreme environments under complex loads (wind, waves, currents, ice, earthquakes), requiring special materials, welding techniques, and corrosion protection.

•Typical Structures: Fixed platforms, mobile platforms (e.g., jack-up, semi-submersible).

2. By Structural System and Load-Bearing Mechanism

This reflects the design philosophy and mechanical principles of structural engineers.

1.Frame Structures

•Description: Composed of beams and columns connected rigidly or pin-jointed to withstand vertical and horizontal loads.

•Subtypes:

•Pure steel frames: Lateral resistance relies on the rigid moment connections of beams and columns.

•Frame-bracing systems: Addition of concentric or eccentric bracing to significantly enhance lateral stiffness.

•Steel frame-concrete core tube hybrid structures: Commonly used in skyscrapers, with the core tube bearing most lateral forces.

2.Truss Structures

•Description: Composed of straight members connected at their ends to form a lattice system. Members primarily bear axial tension or compression, efficiently spanning large distances.

•Common forms: Triangular trusses, arched trusses, parallel chord trusses, etc.

3.Arch Structures

•Description: Transmit loads primarily through axial compression, enabling large column-free spaces and elegant aesthetics.

•Applications: Bridges, stadiums, exhibition halls.

4.Space Grid Structures •Description: Three-dimensional load-bearing systems, lightweight, stiff, and architecturally expressive.

•Subtypes:

•Space trusses:

Often made of steel tubes and spherical nodes, bidirectional load-bearing, commonly used for long-span roofs.

•Latticed shells: Curved surfaces, combining the advantages of trusses and shells. 5.Cable-Membrane and Tensile Structures

•Description: Flexible systems maintained by tension to define form and carry loads, extremely lightweight, enabling very long spans.

•Applications: Stadium canopies, airport roofs, landscape features.

3. By Fabrication and Installation Methods

This reflects the degree of industrial production.

1.Traditional (Heavy) Steel Structures

•Description: Often involve on-site piece-by-piece or batch installation for large projects. Components are large and heavy, with complex connections (high-strength bolts or welding).

•Characteristics: High customization, demanding construction technology. 2.Light Steel Structures

•Description: Utilize thin-walled cold-formed sections (C-purlins, Z-purlins) and light hot-rolled H-sections.

•Characteristics: Economical steel usage, rapid installation.

•Typical example: Portal frames (the absolute mainstream for light industrial buildings). 3.Prefabricated/Modular Steel Structures

•Description: Building decomposed into modular units fabricated in factories (including interior finishes and equipment), then assembled on-site like "building blocks."

•Characteristics: Highest level of industrialization, controlled quality, extremely fast construction.

4. By Connection Method Connection methods are critical to the safety of steel structures.

1.Welded Connections

•Advantages: Simple construction, material-efficient, airtight, high stiffness.

•Disadvantages: Presence of welding residual stresses and deformations, high skill requirements for welders, stringent on-site quality inspection.

2.Bolted Connections

•Common bolts: Mainly used for temporary fixation or connections in secondary structures.

•High-strength friction grip bolts: The most important on-site connection method today. Tightening bolts generates immense friction between plates to transmit shear forces, offering excellent mechanical performance, fatigue resistance, and ease of installation. 3.Riveted Connections

•Description: Historically primary, now largely replaced by high-strength bolted connections, used only in specific retrofits or special cases.

•Characteristics: Good toughness but labor-intensive and material-consuming.

Summary

Classification Dimension | Main Categories | Key Features and Typical Applications |

|---|---|---|

By Purpose | Industrial, Commercial/Public, Bridges, Towers/Masts, Offshore Platforms | Directly corresponds to building function and load requirements |

By Structural System | Frames, Trusses, Arches, Space Grids, Cable-Membrane | Reflects structural mechanics and aesthetic principles |

By Fabrication Method | Traditional Heavy, Light, Prefabricated/Modular | Reflects industrialization, standardization, and construction speed |

By Connection Method | Welded, Bolted (primarily high-strength), Riveted | Critical to structural safety, construction convenience, and quality control |

In practice, a complex steel structure project often combines multiple classifications. For example, a large airport terminal may include frame structures (support areas), space trusses or grids (long-span roof), and cable-membrane structures (entrance canopies), extensively using welded and high-strength bolted connections.

Classification DimensionMain CategoriesKey Features and Typical ApplicationsBy PurposeIndustrial, Commercial/Public, Bridges, Towers/Masts, Offshore PlatformsDirectly corresponds to building function and load requirementsBy Structural SystemFrames, Trusses, Arches, Space Grids, Cable-MembraneReflects structural mechanics and aesthetic principlesBy Fabrication MethodTraditional Heavy, Light, Prefabricated/ModularReflects industrialization, standardization, and construction speedBy Connection MethodWelded, Bolted (primarily high-strength), RivetedCritical to structural safety, construction convenience, and quality control

In practice, a complex steel structure project often combines multiple classifications. For example, a large airport terminal may include frame structures (support areas), space trusses or grids (long-span roof), and cable-membrane structures (entrance canopies), extensively using welded and high-strength bolted connections.