Knowledge

About Steel Structural Components

1. What Are Steel Structural Components?

Steel structural components are basic units made by cutting, welding, bolting, and other processes to shape steel plates and profiles (such as H-beams, I-beams, angle steels, steel pipes, etc.) into desired forms and sizes. These components are used to construct architectural or engineering structures.

You can think of them as the various parts and components needed to build a steel "Lego" model.

2. Main Types and Categories

Steel structural components come in a wide variety and can be classified from different perspectives:

By Load-Bearing Characteristics:

• Primary Load-Bearing Components: Parts that bear the main load of the structure, such as steel columns, steel beams, trusses, and space frames. They form the "skeleton" of the structure.

• Secondary Components: Parts that connect primary components or bear local loads, such as secondary beams, purlins, wall beams, braces, stairs, platforms, etc.

By Shape and Cross-Section:

• H-Beam Components: The most commonly used beams and columns, offering excellent load-bearing performance.

• Box-Section Components: Often used for long-span, heavy-load columns and beams, with superior torsional resistance.

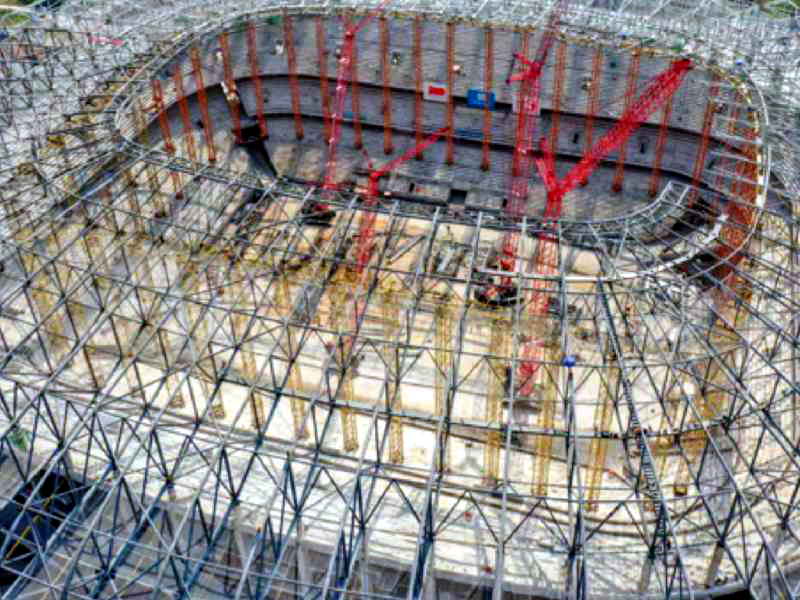

• Truss/Lattice Components: Composed of members forming triangular units, saving material and reducing weight, making them suitable for long-span structures (e.g., stadiums, airport terminals).

• Tubular Truss Components: Trusses welded from round or square tubes, featuring smooth aesthetics and often used in public buildings.

• Special-Shaped Components: Custom-made components with unique shapes for specific architectural needs, such as curved or twisted members.

3. Applications

Steel structural components are widely used in:

• Industrial Buildings: Factories, warehouses, power plants, petrochemical platforms.

• Public Buildings: Stadiums, airport terminals, theaters, exhibition centers, train stations.

• High-Rise and Super-Tall Buildings: Office buildings, hotels, residential complexes.

• Bridge Engineering: Highway bridges, railway bridges, pedestrian overpasses.

• Tower and Mast Structures: Power transmission towers, communication towers, wind turbine towers.

• Others: Ships, offshore platforms, modular buildings, container houses, etc.

4. Production Process

The typical production process for steel structural components includes:

• Detailed Design (BIM/DETAILING): Create detailed processing and installation drawings for each component based on design plans.

• Raw Material Preparation: Procure steel plates, profiles, etc., and conduct material inspections.

• Layout and Marking: Use CNC equipment (e.g., CNC cutting machines) to accurately transfer drawing dimensions onto the steel.

• Cutting: Use flame cutting, plasma cutting, laser cutting, or sawing to shape the materials.

• Hole Drilling and Edge Processing: Process bolt holes with drilling or CNC drilling machines; prepare grooves for welding by edge planning or milling.

• Bending and Forming: Roll bend (cylindrical bending) or press bend steel plates; cold or hot bend profiles.

• Assembly and Welding: Assemble parts into components or entire structures, using welding (primary method) or bolts for temporary fixing and permanent connections. This is a critical step for ensuring quality.

• Correction: Rectify deformations caused by welding to ensure dimensional accuracy.

• Rust Removal and Coating: Perform sandblasting or shot blasting for rust removal, then apply anti-corrosion coatings (primer, intermediate, topcoat) and fire-resistant coatings.

• Inspection and Acceptance: Conduct comprehensive checks on dimensions, welds, coating quality, etc.

• Labeling and Shipping: Number components for easy onsite identification and installation, then package and ship to the construction site.

5. Core Advantages

• High Strength, Light Weight: Lighter than concrete structures, reducing foundation loads and suitable for areas with poor geological conditions.

• Excellent Toughness and Seismic Performance.

• Industrialized Production, Stable Quality: Factory prefabrication ensures high precision and minimal weather-related disruptions.

• Fast Construction Speed: Onsite assembly resembles "building blocks," significantly shortening project timelines.

• Eco-Friendly: Materials are 100% recyclable, with minimal construction waste.

• High Space Utilization: Smaller cross-sections allow for more usable space.