Knowledge

I-Beams VS I-Shaped Steel

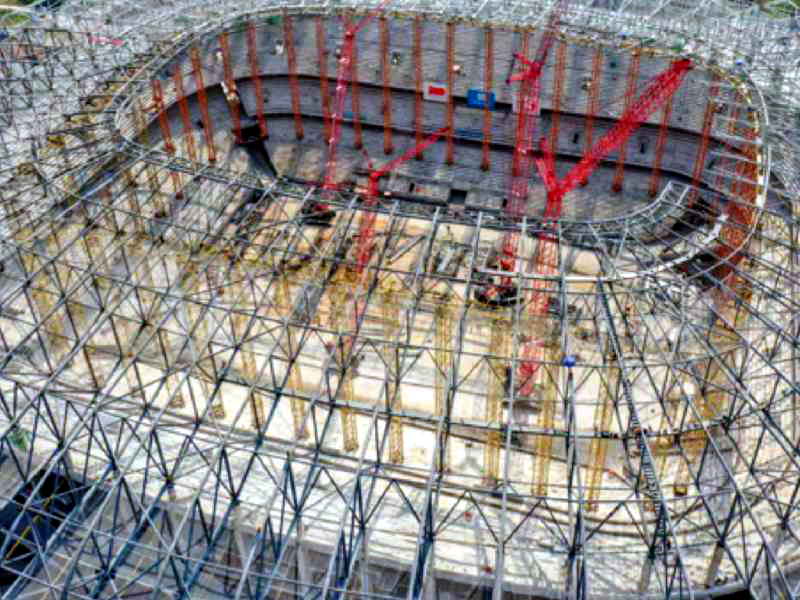

I-Beams: The Backbone of Modern Construction

Introducing I-Beams: The Iconic Symbol of Strength and Efficiency

In the world of structural engineering, few elements are as fundamental and recognizable as the I-Beam. As the workhorse of construction, I-Beams provide the essential framework for buildings, bridges, and infrastructure projects worldwide. Their unique design delivers an unparalleled strength-to-weight ratio, making them the go-to choice for supporting heavy loads over long spans with maximum efficiency and reliability.

What Are I-Beams?

I-Beams, also known as H-Beams or Universal Beams (UB), are structural steel members characterized by their distinctive "I" or "H" cross-section. This shape consists of two horizontal elements (flanges) connected by a vertical element (web). This design is engineered to efficiently resist bending and shear forces, making it exceptionally effective at carrying loads both horizontally as beams and vertically as columns.

Key Features & Benefits:

Superior Strength-to-Weight Ratio: The I-shaped geometry places most of the material in the flanges, away from the neutral axis, maximizing moment of inertia and providing exceptional strength with minimal material usage.

Excellent Load-Bearing Capacity: Ideal for supporting heavy loads over long spans, reducing the need for intermediate supports and enabling open, flexible floor plans.

Versatility in Application: Can function as beams, columns, truss components, or bridging elements, adapting to a wide range of structural roles.

Cost-Effectiveness:

Their material efficiency and ease of installation make them an economical choice for large-scale projects.

Standardization and Availability: Produced in a wide range of standardized sizes (e.g., W-shapes in US, UB/UC in metric systems), ensuring easy sourcing and compatibility.

Ease of Modification and Integration: Can be easily cut, welded, bolted, or reinforced to meet specific project requirements and connected to other structural elements.

Common Types and Sizes:

W-Beams (Wide Flange): The most common type in the US, with parallel flange surfaces.

UB (Universal Beams) & UC (Universal Columns): Standard metric I-beam sections.

IPE (European Standard I-Beams): Characterized by tapered flanges.

HP-Shapes (Bearing Piles): Similar to W-beams but with flanges and webs of equal thickness.

Sizes vary greatly, with depths ranging from 4 inches (100 mm) to over 40 inches (1,000 mm), and weights from tens to hundreds of pounds per foot.

Primary Applications:

I-Beams form the skeleton of countless structures:

Building Construction: Floor and roof beams, columns, and framing in commercial, industrial, and residential buildings.

Bridge Construction: Main girders, piers, and support structures for road and rail bridges.

Industrial Facilities:

Support structures for cranes, heavy machinery, mezzanines, and warehouse racks.

Infrastructure Projects: Foundations, retaining walls, and support systems for tunnels and overpasses.

Shipbuilding and Heavy Equipment: Used in the chassis of large vehicles, ships, and industrial equipment.

Why Choose Our I-Beams?

We supply high-quality I-Beams that meet rigorous international standards (ASTM, AISC, EN). Our products are available in a comprehensive range of sizes and grades, with options for various finishes, including mill scale, painted, or galvanized. Our technical team can help you select the optimal beam size and specification for your project’s load requirements and design goals.

Build on a Foundation of Strength and Reliability.

Contact us today for expert guidance, to request our full product catalog, or to get a competitive quote on the I-Beams that will form the backbone of your next project.